Services Terms

Here is a glossary list of common vocabulary terms used within different sections of IDS, organized by service category.

Bindery/Folding | Data Conversion | Envelopes | File Formats | Forms | Microfilm | Packaging | Paper | Prepress | Press/Printing | Proofs | Scanning | Xerography

Bindery/Folding

Collate:

To gather together in order for binding.

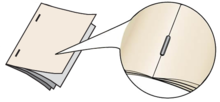

Corner Stitch:

A single staple binding several pages in the corner of the front cover.

Drill/Punch:

The process used to place a hole on a page. Specifications should indicate how many holes, the size of the holes and how they are placed. i.e. 3 hole drill on the left edge 1/4" holes 2 1/2" center to center, or include a drill sample or binder that the material will go into.

Micro-perf:

A hole or ulceration of holes that are smaller than a normal perforation to be conducive to being smoother and holding together better.

Padding:

A number of sheets of paper glued along one edge.

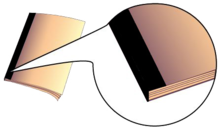

Perfect bind:

A binding for books that wraps the cover paper around the book, so that the spine is the same paper as the back and front covers. This process uses glue to bind the pages together to the cover. This process is best used for books with large page counts (60 pages or more). When designing perfect bind covers keep in mind that a spine width needs to be determined by the paper weight and page count. Extra trim must be furnished on covers for the binder to allow for a glue trap.

Plastic comb bind:

The bound material is punched and a plastic cylinder with teeth or a comb is inserted in the holes to hold the book together. Commonly referred to in centralized printing as spiral binding.

Perforation:

A pierced row of holes to facilitate tearing.

Saddle stitch:

Two metal staples that bind a booklet. Page counts must be divisible by four for this binding process. Based on a 60# offset stock maximum page count for saddle stitching is 100 pages, this will vary dependent on paper weights.

Side stitch:

Two metal staples that bind a booklet edge on top of the front cover.

Spiral bind:

One piece of coiling metal wire inserted through holes punched along the binding side of a book.

Tape bind:

Process using an external strip of tape.

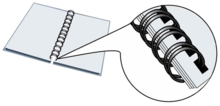

Wire-o-bind:

A continuous double series of wire loops run through punched slots along the binding edge of a booklet.

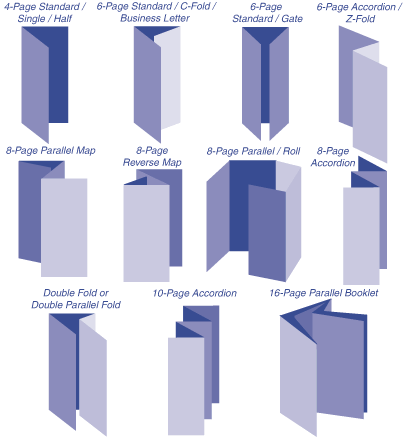

FOLDING

The examples below include:

- Full sheet (8 1/2 x 11) Fold in half = 4-page panels (Standard)

- Full sheet (8 1/2 x 11) Tri-fold/C-fold = 6-page panels - brochure/business letter style (Standard)

- Full sheet (8 1/2 x 11) Gate-fold = 6-page panels - sides fold inwards like a gate

- Full sheet (8 1/2 x 11) Accordian/Z-fold = 6-page panels - opens like an accordian

- Full sheet (8 1/2 x 14) Parallel Map = 8-page panels - opens like a folded map

- Full sheet (8 1/2 x 14) Reverse Map = 8-page panels - opens like a folded map in reverse order

- Full sheet/Legal Size (8 1/2 x 14) Parallel/Roll = 8-page panels - opens like rolling out paper

- Full sheet/Legal Size (8 1/2 x 14) Accordian = 8-page panels - opens like an accordian

- Full sheet/Legal Size (8 1/2 x 14) Double-fold/Double Parallel = 8-page panels - opens like two sheets of paper together

- Full sheet/Legal Size (8 1/2 x 14 or 11 x 17) Accordian = 10-page panels - opens like an accordian

- Full sheet (Multiple Sizes) Parallet/Booklet = 16-page - opens like a booklet

If you would like to see a physical sample of these different folds, contact our Account Management Team.

Envelopes

Bang tail envelope:

A #9 remittance envelope that has a long flap to allow printing of additional information or instructions.

Booklet envelope: An envelope that opens on the side and is available in a variety of sizes 9 x 12, 10 x 13 etc.

Catalog envelope:

An envelope that is open on the end and is available in a variety of sizes such as 9 x 12, 10 x 13, etc.

#10 envelope:

Standard mailing envelope, overall size 4 1/8x 9 1/2.

#10 Window envelope:

Overall size of 4 1/8 x 9 1/2 with a standard window size of 1 1/8 x 4 1/4 located 7/8" from the left and 1/2" from the bottom.

Reply envelope:

#9 envelope that fits inside a #10 and is addressed so the recipient may mail back information to the originating agency.

Post card:

A single card that is mailable, minimum height of 3 1/2 x minimum length of 5 inches and maximum height of 4 1/4 x maximum length of 6 inches without incurring additional postage costs. Stock must caliper .07 (90# index, or 7pt card stock)

File Formats

EPS:

EPS (Encapsulated Postscript) is a vector format designed for printing to PostScript printers and imagesetters. It is considered the best choice of graphics format for high resolution printing of illustrations. EPS files are created and edited in illustration programs such as Adobe Illustrator. They are saved with the .eps file extension.

JPEG:

JPEG (Joint Photographers Expert Group) is a compression algorithm used to compress color and grayscale images down to 5% of their uncompressed size. Lossy compression means that some of the data in the original file is lost as a result of the abbreviation of information being used. They are saved with the .jpg extension

GIF:

GIF (Graphics Interchange Format) is a graphics file format that allows data compression and image files to be exchanged across multiple platforms, and are widely used on the Web to display indexed-color graphics and images, not meant for print.

PDF:

PDF (Portable Document Format) is a file format developed by Adobe Systems which captures all the elements of the original file, text, graphics, font, layout etc. PDFs are in wide use on the web and offer great versatility for distributing and sharing information. See Adobe.com for information and/or to download a free copy of Acrobat Reader.

TIFF:

TIFF (Tagged Image File Format)is a standard format for image files. TIFF is operating system and display device independent. TIFF files can be in any of several classes, including black & white (bitonal), grayscale, or color, and can include CCITT Group 4, JPEG, or LZW compression. They are saved with the .tif extension.

Vector:

Vector graphics are a resolution-independent, scalable format composed of individual objects made up of mathematical calculations. Vector images can be resized easily without loss of quality making them an ideal format for initial design of logos and illustrations that to be used at multiple sizes. Illustration or drawing software such as Adobe Illustrator are popular graphics software for creating and editing vector graphics.

Forms

Carbon interleaf:

A multi-part form with a carbon sheet between identified parts.

Crimped:

A process that is used to hold several parts of a continuous feed form together. Crimps are placed in the pinfeed area of the form.

Pinfeed:

Also known as tracker feed.

Snap apart form:

A multi-part form attached along one edge with a glued stub normally 3/4" wide.

Microfilm

Microfiche:

A transparent sheet of photographic film containing images arranged in a series of rows (grid) and having a heading that contains identifying information in text that is large enough to be read without magnification. The most common microfiche are made by filming textual or graphic material at a reduction ratio of approximately 24:1 and usually accommodate 5 rows of images.

Microfilm:

Although the term is used for the photographic film that is employed in producing microforms in general, it is also specifically used to designate the long strips of photographic film that are mounted on reels, in cartridges, and in cassettes. The strips of film together with the containers that house them are called, respectively, microfilm reels, microfilm cartridges, and microfilm cassettes. They are all roll formats in which micro images appear in linear rather than grid array.

Packaging

Paper band:

A thick paper strip with an adhesive back that is wrapped around a given number of units, less expensive than shrink wrapping, and causes less damage to materials than rubber banding.

Shrink-wrap:

A process of wrapping a given number of units in plastic, then using a heat chamber to shrink the plastic to a tight fit.

Skid pack:

A packing method where materials are stacked on a pallet and encased in cardboard and plastic wrap. This is a less expensive way of packaging and most often used if shipping to a mailer or bindery for additional work. The drawback is that it could result in greater percent of damaged goods.

Slip sheet:

A process of inserting colored sheets of paper to sort printed materials.

Paper

Basis weight:

The weight in pounds of a ream (500 sheets) of paper cut to a given standard size for that grade, e.g., 500 sheets 25 x 38 in. of 50-lb book paper weight 50 pounds.

Bond paper:

A grade of writing or printing paper where the strength, durability, and permanence are essential requirements, used for letterheads, business forms, etc.

Book paper:

A general term for coated and uncoated papers.

Carbonless paper:

NCR paper is a coated paper that will give you multiple copies without carbon.

Coated paper:

Paper having a surface coating which produces a smooth finish, e.g., gloss, dull, and matte papers.

Deckle edge:

The untrimmed feathery edges of paper formed where the pulp flows against the deckle.

Finish:

Paper comes in different textures or finishes, e,g, gloss, matte, dull, felt, laid, cockle, and smooth.

Grain:

Paper is made from fibers that run in one directions of the paper this is called the grain. Projects fold best when the fold runs with the grain, not against the grain.

Holdout:

In printing, a property of coated paper with low ink absorption which allows ink to sit on the surface with high gloss. Too much holdout causes problems with set-off.

Kraft:

A paper or board containing unbleached wood pulp (brown in color) made by the sulfate process.

Laid:

Paper with a pattern of parallel lines at equal intervals, giving a rib effect.

Matte:

Dull finish paper without gloss or luster.

Newsprint:

Paper made mostly of groundwood pulp and small amounts of chemical pulp, used for printing newspapers.

Plus cover:

A booklet that has a cover that is of a different weight, color, or finish than that of the inside pages.

Ream:

500 sheets of paper.

Recycled paper:

To meet state requirements, it must be 20% post consumer waste.

Self cover:

A booklet in which the cover paper is the same weight and color as the body of the book.

Tooth:

A characteristic of paper, a slightly rough finish, which permits it to take ink readily.

Prepress

Bleed:

A term used when the design or copy runs off the trim area of the page. It is important for the printer to know whether it bleeds to plan the correct size press sheet.

Camera -ready art:

Artwork that is supplied with color breaks, trim marks, and folding marks.

Color correction:

Any method such as masking, dot etching, re-etching, and scanning to improve color rendition.

DPI - Dots per inch:

A measure of the resolution of a screen image or printed page. Most jobs can be run at 1200 DPI for film output, high-end printing may require 2400 DPI, but requires more time and expense.

Dummy:

A preliminary layout showing the position of illustrations and text as they are to appear in the final reproduction. A set of blank pages made up ahead of time to show size, shape, form, and general style of a piece of printing.

Duo-tone:

A halftone that is printed in two colors.

Folio:

The page number.

Font:

A complete assortment of letters, numbers, and punctuation marks of a given size and design.

FPO:

(for position only) In digital imaging a low resolution image positioned in a document to be replaced later with a higher resolution version of the same image.

Halftones:

A technique of representing shadings by dots produced by photographing the image behind a fine screen.

Line screen:

This defines the dots per inch in a screen, commonly used line screens come in 88, 133, 150 and 200. The 88-line screen is used in newsprint production, 133 is used for uncoated stocks and 150 and 200 are used for coated stocks.

PMS colors:

PMS stands for Pantone Matching System. These colors are special mixes of ink to create solid unique colors.

PostScript:

A page description language developed by Adobe Systems, Inc. to describe an image for printing. It handles both text and graphics.

Preflight:

In digital prepress, the test used to evaluate or analyze every component needed to produce a printing job. Preflight confirms the type of disk being submitted, the color gamut, color breaks, fonts, and any art required (illustrations, transparencies, reflective photos, etc.) plus layout files, page sizes, print driver, crop marks etc.

Screen build:

The practice of using four-color process screening to create a desired PMS color.

Screen percentage:

A method to create different color hues by using a dot pattern or screen of a solid color. Screen percentages run from 10% of the original color (the lightest ) to 90% (the darkest).

Transparency:

A positive film or slide, having a picture or design that is visible when light shines through it or that can be projected on a screen.

Trapping:

Ink transfer to previously printed ink rather than unprinted paper. Commonly used in film production to describe the slight increase (fatty) and decrease (shrinking) to the design to create a slight overlap between adjacent colors printed on a sheet of paper to avoid a white line of paper show through.

Separations:

Color separation is the process by which original artwork is separated into individual color components for printing. The components are cyan, magenta, yellow, and black known as CMYK.

Press/Printing

Back bone:

The back of a bound book connecting the two covers also called the spine.

Consecutive numbering:

A security feature that sequentially numbers each form.

Die cut:

A process of cutting paper in shapes or angles that are not square. This requires producing a metal die from a pattern.

Digital Printing:

It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers. The image is sent directly to the printer using digital files such as PDFs.

Face:

The cut side of a book opposite the binding edge.

Foil Stamp:

A process of adhering a thin sheet of metallic foil to paper using a press stamping processes. Foils are available in a range of colors, most commonly gold and silver.

Foot:

The bottom of the page.

Four-color process:

The four process colors are cyan, magenta, yellow, and black. By using these colors as screen builds you can create four color photos and unique colors.

Gripper edge:

The leading edge of paper as it passes through a printing press. Also the front edge of a lithographic plate that is secured to the front clamp of the plate cylinder.

Gutter:

The bound side of the page.

Head:

The top of the page.

Hickeys:

Spots or imperfections in the printing due to dirt on the press, dried ink skin, paper particles, etc.

Make-ready:

In printing, all work done to set up a press for printing.

Opaque ink:

An ink that conceals all color beneath it.

Over printing:

Double printing, printing over an area that already has been printed.

Picking:

In printing, the lifting of the paper surface during printing. It occurs when the pulling force (tack) of the ink is greater than the surface of the paper.

Set-off:

In presswork, when the ink of a printed sheet rubs off or marks the next sheet as it is being delivered.

Signature:

A large sheet of paper in which a number of pages are laid out in some multiple of four, and when folded to page size, forms a section of a book.

Show-through:

In printing, the undesirable condition in which printing on one side of the sheet can be seen through the paper under normal lighting conditions.

U.V. Inks:

A solventless ink that are cured by U.V. radiation. Used extensively in screen printing.

Variable printing:

Variable Data Printing (VDP) is a form of digital printing, including on-demand printing, in which elements such as text, graphics, and images may be changed from one printed piece to the next without hindering the printing process, and using information from a database or external file.

Varnish:

A thin, protective coating applied to a printed sheet for protection or appearance. Available in either gloss or dull finish.

Web press:

A press that prints on a roll or web-fed paper. Used for large quantities, runs at high speeds.

Wrinkles:

Creases in the press sheet occurring during printing.

Proofs

Laser proof:

A proof from a laser printer, best used to check position and layout and pagination.

Press check:

A process where the customer goes to the vendor's plant to check color match while the job is on the printer's press. Used when quality is critical - high end printed pieces. This process does incur additional costs.

Press proof:

A proof that is furnished from the press run folded to size.

Xerography

Color copies:

Digital reproduction using toners that are in the four process colors, magenta, cyan, yellow, and black.

Docutech:

A high speed copier that can digitally reproduce your work in black using toner. The machine allows you to add set labeling to newsletters, scan and crop photos, and run multiple colors of stock.

Join Our IDS Services Newsletter

Customer Account Management Team

Denver: Email DPA_IDSCustomerService

Pueblo: 719-948-0053 | Email DPA_IDSCustomerService

IDS Hours of Operation

Northern Region/Denver - 7:00 a.m. - 5:00 p.m. | Mon. - Fri.

Southern Region/Pueblo - 8:00 a.m. - 5:00 p.m. | Mon. - Fri.