Printing

Below are various types of printed products we produce. To see a portfolio of finished product examples, go to our Graphic Design page.

- Advertisements (print or digital)

- Annual Reports (print or digital)

- Books (hard or soft cover)

- Business Cards

- Brochures, Flyers, Rack Cards (marketing collateral)

- Catalogs (print or digital)

- Calendars

- Conference Materials — signage, posters, banners (large format displays/trade show booths - vinyl, paper, cloth)

- Direct Mail — postcards, business replies, surveys (pieces or packets)

- Forms (print or digital/PDF fillable)

- Posters (large & small format)

- Specialty — self-stick posters, signage, labels, promotional items (buttons, stickers, etc.)

- Transactional Print — statements, postcards, notices

Digital Printing and Document Copying

Digital printing and copying typically refers to any type of print reproduction method that utilizes electronic files to produce a printed piece from liquid and dry ink or toner.

Electronic printing means that each copy produced is a first-generation original equal to, or better than, what the customer would have sent to IDS as artwork and is more convenient than delivering originals.

IDS Digital Printing is the fastest, most convenient, and economical method of duplicating between 500 or more printed copies of your black or color documents. IDS is very competitive with the private sector, and has demonstrated a savings of 50% or more in many digital instances. For information on current pricing, click here.

Variable Data Printing

Variable data printing (VDP) is a form of digital printing, including on-demand printing, in which elements such as text, graphics, and images may be changed from one printed piece to the next, without stopping or slowing down the printing process and using information from a database or external file.

VDP mobilizes computer databases, digital print devices, and highly effective software to create high-quality, full color documents, with a look and feel comparable to conventional offset printing.

All variable data printing begins with a basic design that defines static elements and variable fields for the pieces to be printed. While the static elements appear exactly the same on each piece, the variable fields are filled in with text or images as dictated by a set of application and style rules and the information contained in the database.

There are several levels of variable printing. The most basic level involves changing the salutation or name on each copy much like mail merge. More complicated variable data printing uses 'versioning', where there may be differing amounts of customization for different markets, with text and images changing for groups of addresses based upon which segment of the market is being addressed. Finally there is full variability printing, where the text and images can be altered for each individual address.

Commercial Printing

IDS has an extensive roster of commercial printing resources to meet virtually any printing need. IDS leverages volume-based buying to secure the best possible value for the customer base. When determining if services will meet the customer’s needs, IDS will evaluate specific projects and determine if the needs can be met with IDS partners, or if a customer may be able to procure services at a better price via the competitive bidding process.

Bindery & Folding

There are various ways that printed materials can be bound. Listed below are some terms and examples of standard bindery and folding methods. IDS can provide printed samples of each style upon request.

Collate:

To gather together in order for binding.

Corner Stitch:

A single staple binding several pages in the corner of the front cover.

Drill/Punch:

The process used to place a hole on a page. Specifications should indicate how many holes, the size of the holes and how they are placed. i.e. 3 hole drill on the left edge 1/4" holes 2 1/2" center to center, or include a drill sample or binder that the material will go into.

Micro-perf:

A hole or ulceration of holes that are smaller than a normal perforation to be conducive to being smoother and holding together better.

Padding:

A number of sheets of paper glued along one edge.

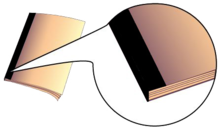

Perfect bind:

A binding for books that wraps the cover paper around the book, so that the spine is the same paper as the back and front covers. This process uses glue to bind the pages together to the cover. This process is best used for books with large page counts (60 pages or more). When designing perfect bind covers keep in mind that a spine width needs to be determined by the paper weight and page count. Extra trim must be furnished on covers for the binder to allow for a glue trap.

Plastic comb bind:

The bound material is punched and a plastic cylinder with teeth or a comb is inserted in the holes to hold the book together. Commonly referred to in centralized printing as spiral binding.

Perforation:

A pierced row of holes to facilitate tearing.

Saddle stitch:

Two metal staples that bind a booklet. Page counts must be divisible by four for this binding process. Based on a 60# offset stock maximum page count for saddle stitching is 100 pages, this will vary dependent on paper weights.

Side stitch:

Two metal staples that bind a booklet edge on top of the front cover.

Spiral bind:

One piece of coiling metal wire inserted through holes punched along the binding side of a book.

Tape bind:

Process using an external strip of tape.

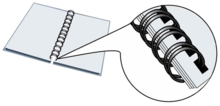

Wire-o-bind:

A continuous double series of wire loops run through punched slots along the binding edge of a booklet.

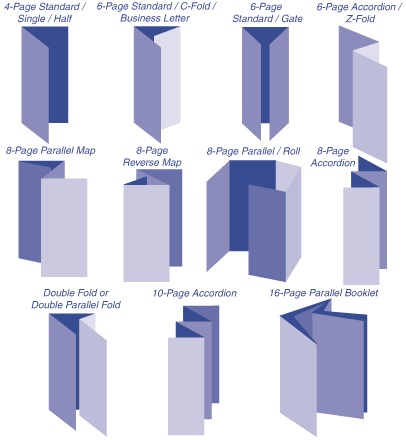

FOLDING

Below are examples of different types of folding for basic folding projects that can be used with different size sheets of paper. The examples below include:

- Full sheet (8 1/2 x 11) Fold in half = 4-page panels (Standard)

- Full sheet (8 1/2 x 11) Tri-fold/C-fold = 6-page panels - brochure/business letter style (Standard)

- Full sheet (8 1/2 x 11) Gate-fold = 6-page panels - sides fold inwards like a gate

- Full sheet (8 1/2 x 11) Accordian/Z-fold = 6-page panels - opens like an accordian

- Full sheet (8 1/2 x 14) Parallel Map = 8-page panels - opens like a folded map

- Full sheet (8 1/2 x 14) Reverse Map = 8-page panels - opens like a folded map in reverse order

- Full sheet/Legal Size (8 1/2 x 14) Parallel/Roll = 8-page panels - opens like rolling out paper

- Full sheet/Legal Size (8 1/2 x 14) Accordian = 8-page panels - opens like an accordian

- Full sheet/Legal Size (8 1/2 x 14) Double-fold/Double Parallel = 8-page panels - opens like two sheets of paper together

- Full sheet/Legal Size (8 1/2 x 14 or 11 x 17) Accordian = 10-page panels - opens like an accordian

- Full sheet (Multiple Sizes) Parallet/Booklet = 16-page - opens like a booklet

If you would like to see a physical sample of these different folds, contact our Account Management Team.

Join Our IDS Services Newsletter

Customer Account Management Team

Denver: Email DPA_IDSCustomerService

Pueblo: 719-948-0053 | Email DPA_IDSCustomerService

IDS Hours of Operation

Northern Region/Denver - 7:00 a.m. - 5:00 p.m. | Mon. - Fri.

Southern Region/Pueblo - 8:00 a.m. - 5:00 p.m. | Mon. - Fri.